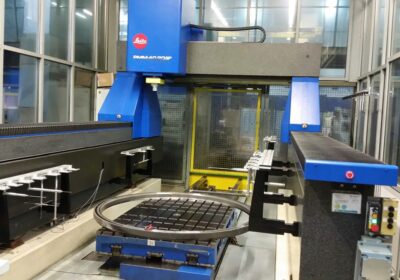

Prima Power

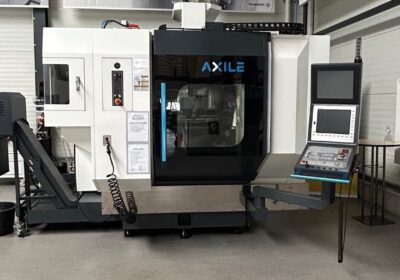

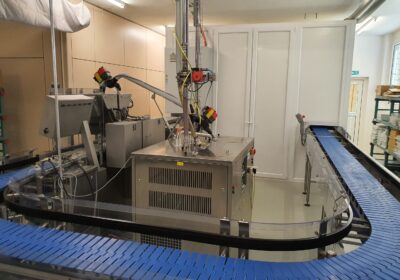

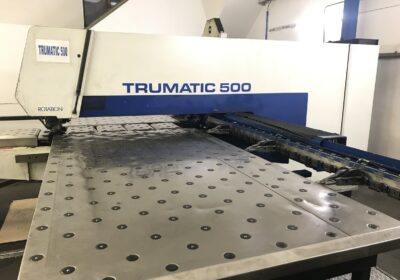

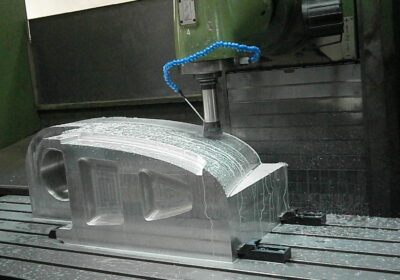

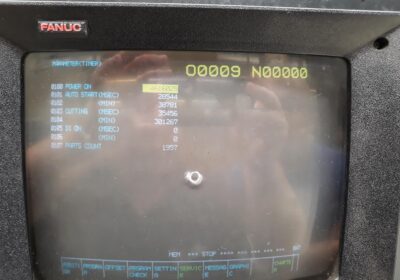

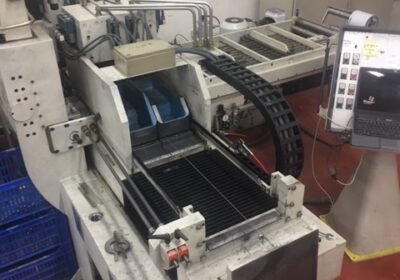

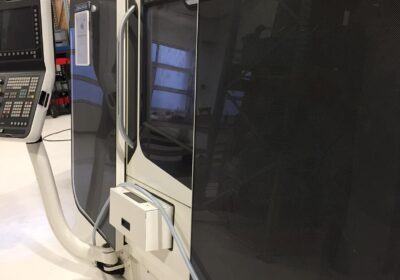

3 KW FIBER LASER COMBINED MACHINE AND ELECTRIC PUNCHING MACHINE Machine combined with IPG PHOTONICS 3 kw laser and electric punching turret, acquired in 2015, is in perfect condition. All revisions and maintenance have been performed by the Official Technical Service. It is currently in operation. The car has a work area of 1900 x 1565 (without repositioning), being able to reach 3074 x 1565 (with replacement) and with a combined moving speed of 90m / min. The laser resonator IPG YLS 3000, with a maximum power of 3 kw and being able to cut thicknesses of 8 mm in pickled steel and 6 mm in stainless steel. Everything is controlled by a keyboard and color touch screen located on the machine foot control. The transmission of the programs can be done via USB or by direct network connection between the control and a computer. Includes NC Express e3 licensed programming software. -. Complete characteristics: BRAND: PrimaPower MODEL: LPe6xf MANUFACTURING DATE: 2015 DIMENSIONS: 22000 x 6600 Loading tower: -. It integrates a tower for the feeding of raw sheet with capacity for ten packages of sheet, in which you can have the different types of sheet that are going to be cut in the machine . LST 6: -. It is an automatic loading and classification system. Load the material into the machine. It also collects the finished pieces and classifies them according to the location programmed in the two unloading tables (lower and upper) Punching system: -.The turret has a force of 230 kN and is composed of 20 stations (4 "A", 9 "B" two of them index, 3 "C" one of them index, 4 "D" two of them index). In the index stations of the "D" a multi-tool tool with a capacity of 6 punches of the station "A" and another to use the threading tool is mounted. MULTI-THREAD (MT6-TFi) -. The MT6-TFi automatic threading tool can make threads in all materials up to 8 mm thick, from M-2.5 to M-10. LASER -.Composed by an IPG YLS-3000 resonator, 5 ”or 7.5” Primapower cutting head for the lens, it can cut thicknesses of 8 mm in carbon steel and 6 mm in stainless steel, also cutting various materials such as copper, wood, etc. CLASSIFICATION SYSTEM - In addition to the LST6 classification system, the machine also contains different methods for the classification of different parts and remnants. In both the punching zone and the laser zone, the machine has two hatches with a maximum piece size of 500 x 500. - The laser trap door contains, in turn, conveyor belts (scraps and pieces), by means of which the scraps and pieces are classified in different sorting drawers, according to their programming. RETALS SYSTEM - At the end of cutting the sheet, by means of a comb system and a mobile table, leave the sheet metal scrap in the area of discharge of scrap. Hours: -. Resonator: 21696 h.

Pris: On request