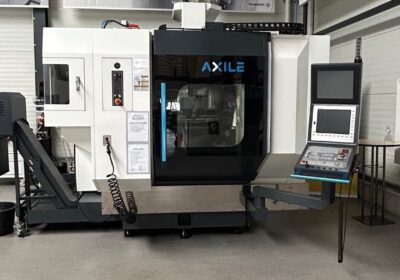

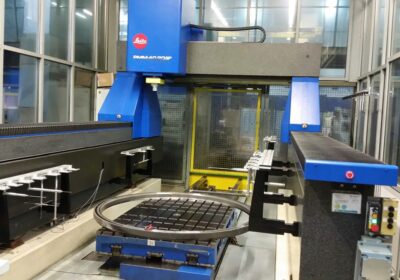

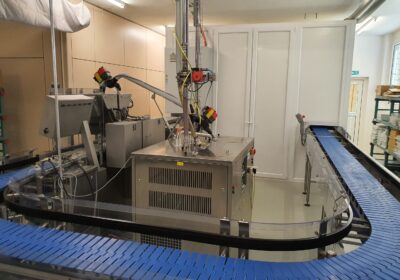

Dalcos PXN 2003

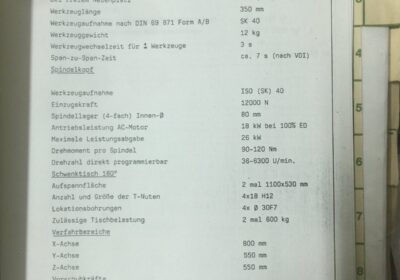

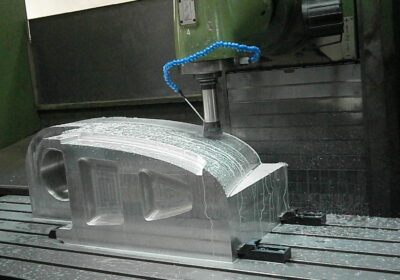

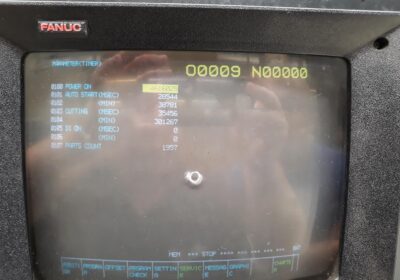

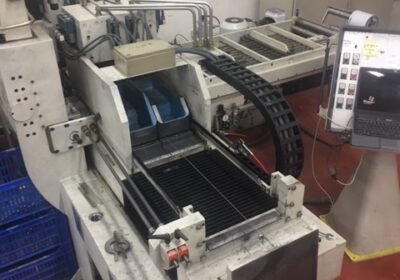

Maskinbeskrivning – CNC Stansmaskin | Dalcos Vega System Maskinen har arbetat ungefär 50 000 timmar sedan inköpet. Den har kontinuerligt underhållits och smörjts och är fortfarande i bruk, om än mer sällan. Maskinens verktyg har anpassats för vårt specifika användningsområde och möjliggör stansning av tunna material ner till 0,2 mm tjocklek nästan helt utan grader. Maskinen har fyra verktygsbågar, var och en med 2 C-stationer och 3 B-stationer, totalt 8 C- och 12 B-stationer. Verktygen rör sig i Y-led på två separata vagnar, vilket möjliggör matning av materialremsa upp till 400 mm bredd. CNC-matningen sker via Dalcos patenterade Vega-matning. Stansningskraften kommer från en hydraulisk enhet på 250 psi, som levererar upp till 8 ton stansningskraft per station. Materialet klipps av i slutet av stansen med en 10 ton skärkniv. Styrningen av elskåpet sker via en PC-konsol. Remsan matas ut från en avvikare med kapacitet på 1,25 ton, med både manuell och automatisk loop-kontroll. Maskinen levereras med anpassade verktygshållare för alla stationer (B och C) samt självcentrerande dörhållare i varje verktygshållare. Dessa verktygsbågar kan bytas ut om du vill använda standard Amada thick turret-verktyg eller andra typer – detta måste göras i samarbete med Dalcos Italien. SEO-nyckelord: CNC stansmaskin till salu hydraulisk stansmaskin Dalcos Vega matning stansning av tunna material 0,2 mm plåtbearbetningsmaskin Amada-kompatibla verktyg begagnad CNC-maskin B och C stationer verktyg automatisk plåtmatare industrimaskiner i Sverige