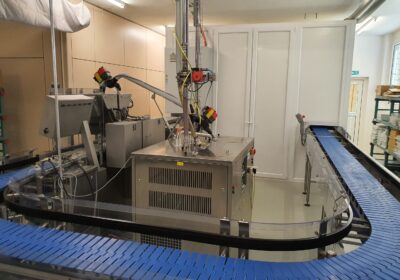

NILPETER MO3300

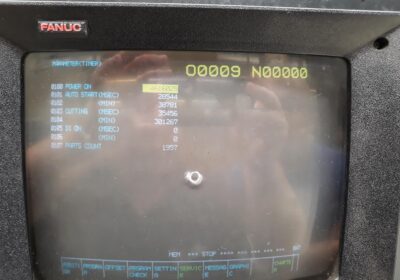

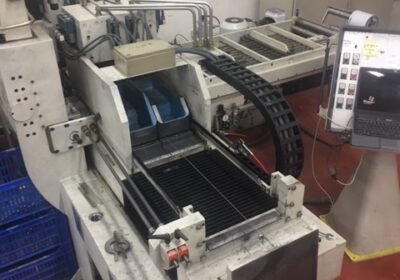

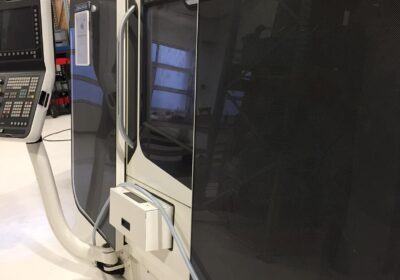

Basic Machine Structure: 8 Colours, thereof 6x Offset (DW2-DW7) 1 Punching Unit, Register Control 1) Unwinding: with Roll Lifter andamp; edge Control 2) Move-in Station: with Corona System Vetaphone 2kW andamp; Teknec Web cleaning 3) M-Station: (First Platform) Delam-Relam andamp; Turning Cross 4-7) MO Stations: GMI Mircocolor 1 Colour control System andamp; Siphon control andamp; Ink Agitator 8) M-Station 9) Punching Unit: with Pull Station andamp; 1 Punching Unit 15"-25" L+B Gapmaster 10) Rewind Unit: with Grid Rewinder andamp; Label Converter andamp; BST Camera 11) Gew UV System: VCP with cooling Drums DW 1+2 reinforced Lamp System for Screen printing 12) Cooling Unicold TAE 081 13) Baldwin Water Treatment (NEW 2019) 14) Main Control Panel 15) GMI Control Panel Offset inserts: 4 x 6 pieces – 20“, 22“, 24“, 25“ Screen printing inserts: 3 Stork RSI Flexo Inserts: 2 Chamber Squeegee andamp; Paint Pump Flexo Insert with Lamination Unit: 1 + Cold Embossing Plate Bending System: 1 Transport Trolley for Slide-in Units: 4 System Plates for Storage: 30