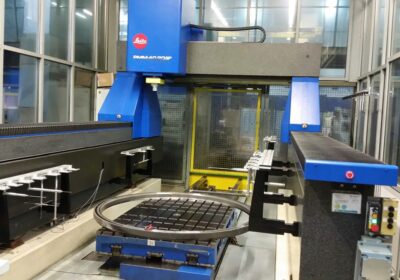

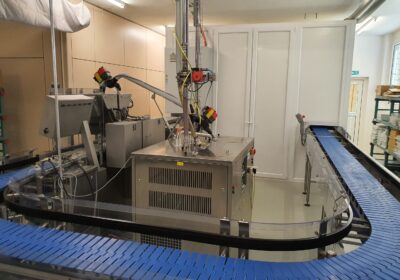

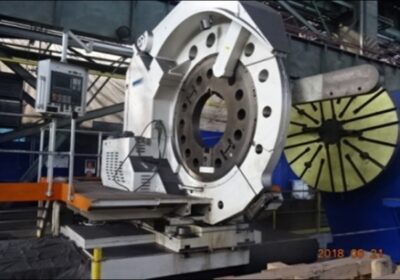

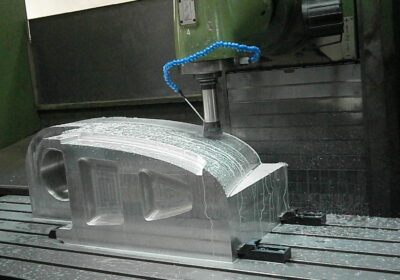

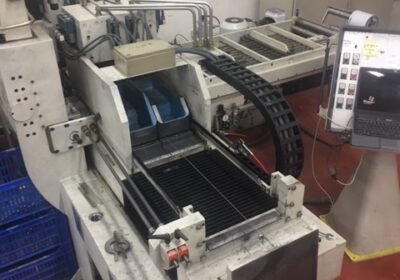

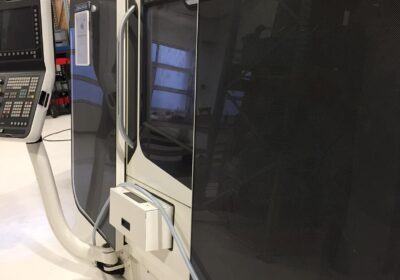

Special production line for mechanical processing of cooling elements for AC-DC-Inverter

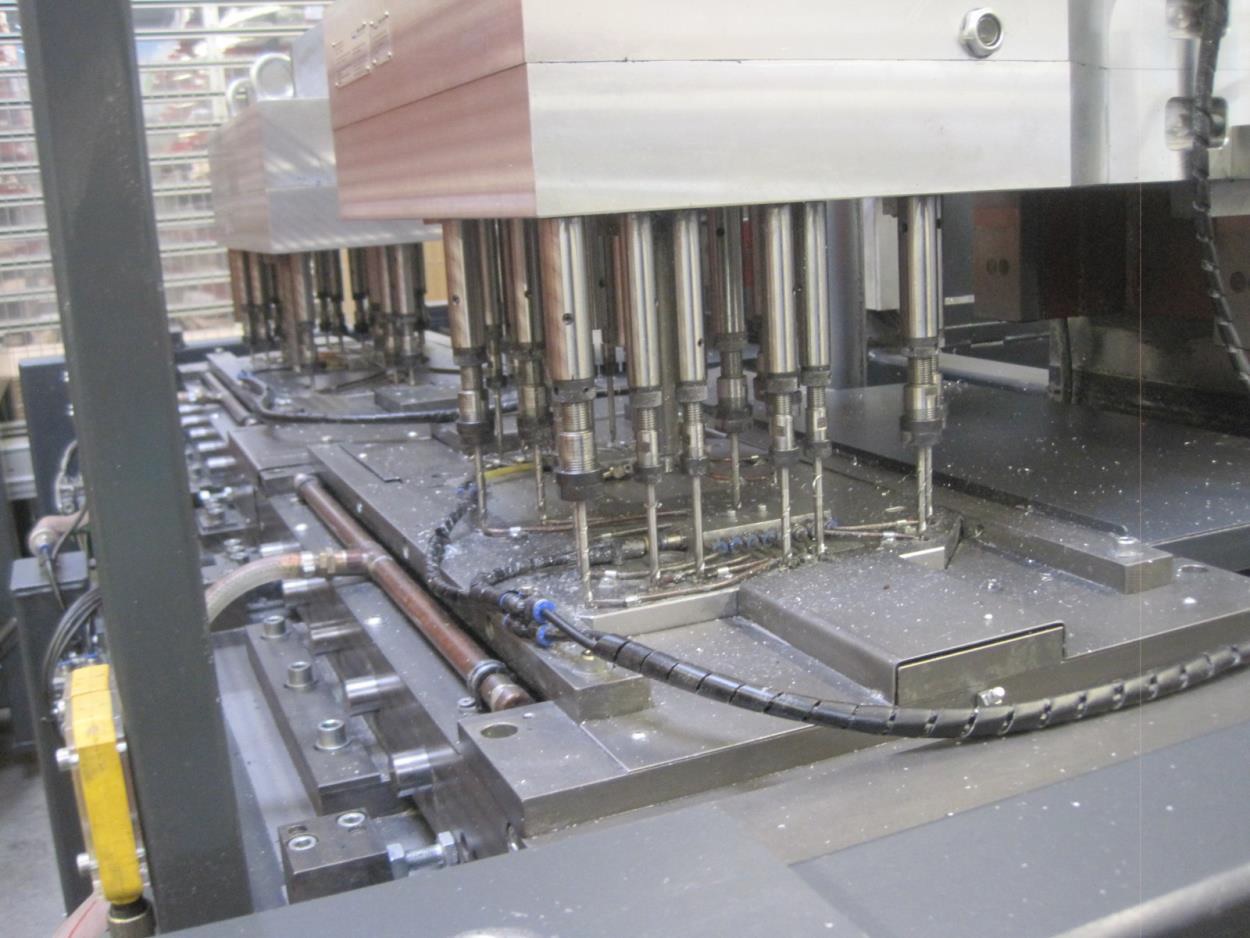

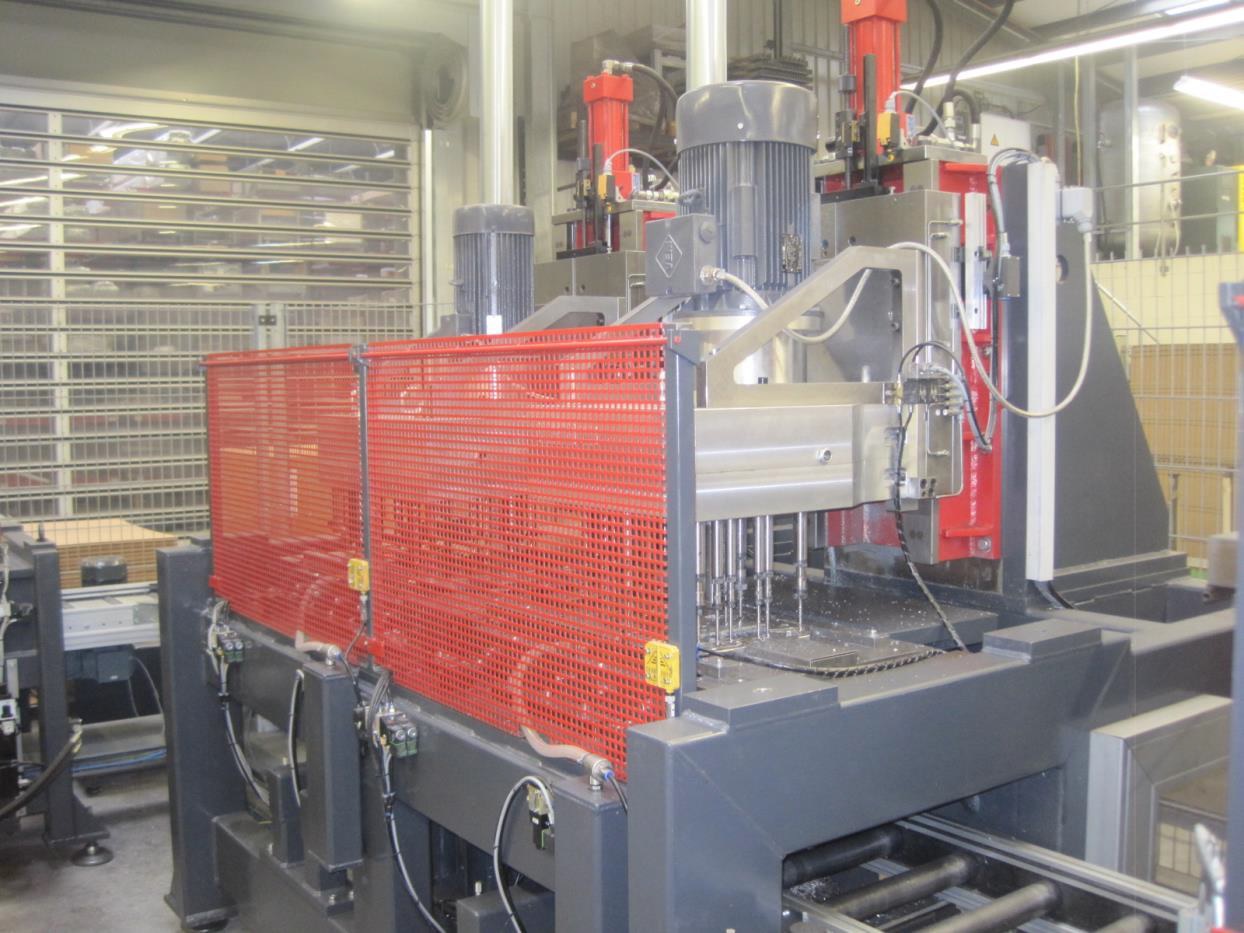

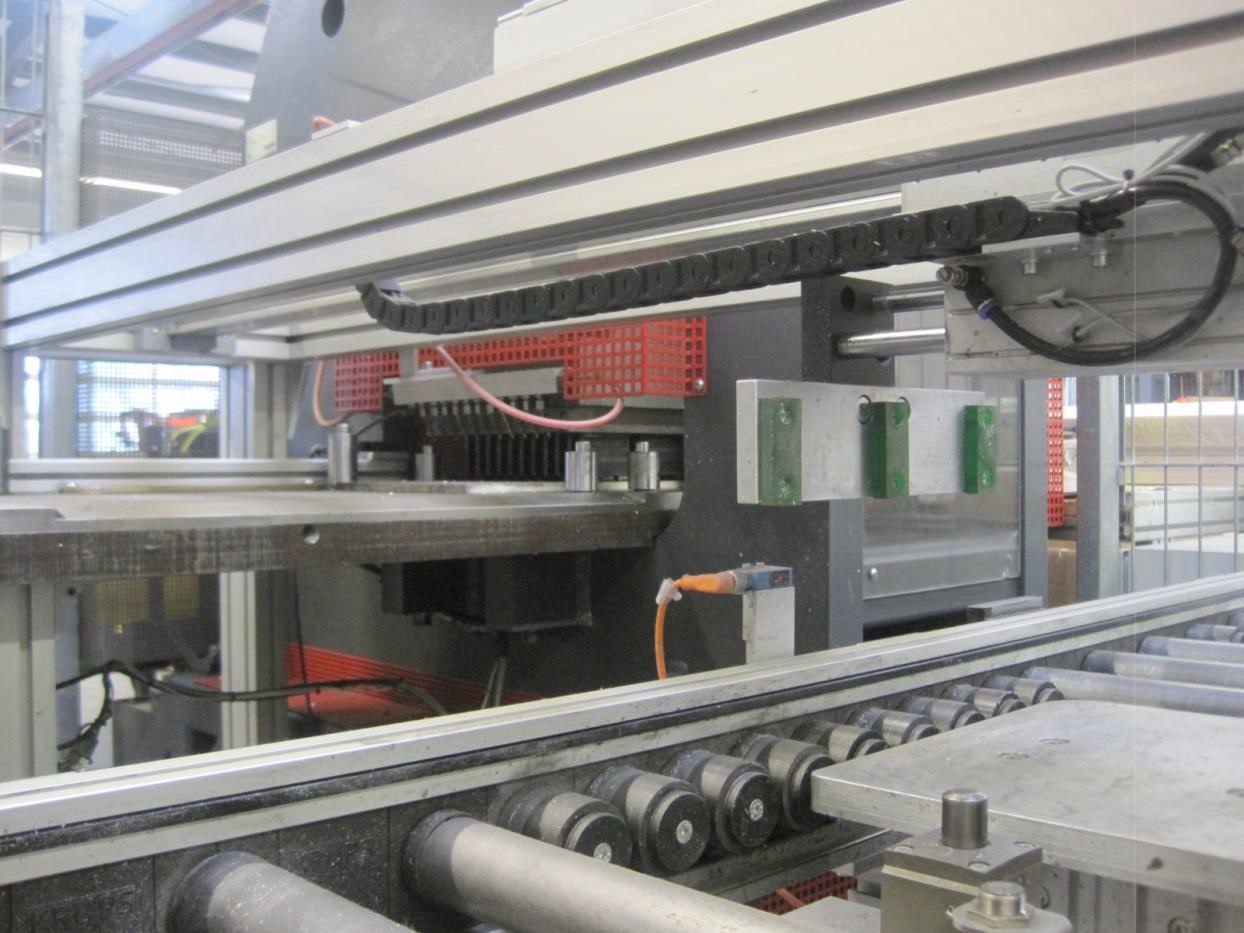

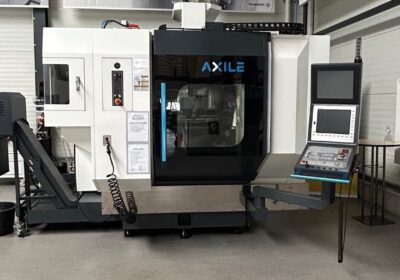

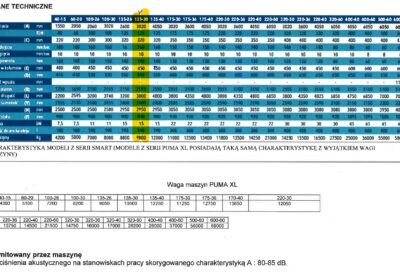

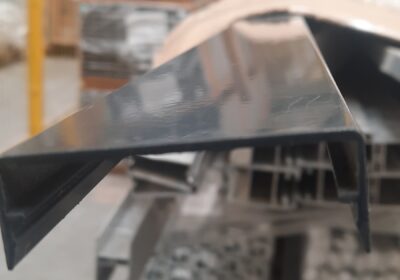

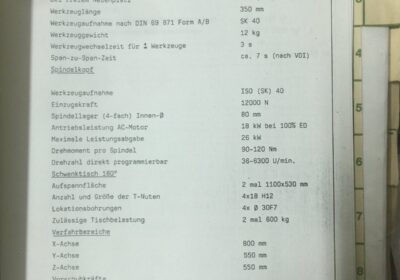

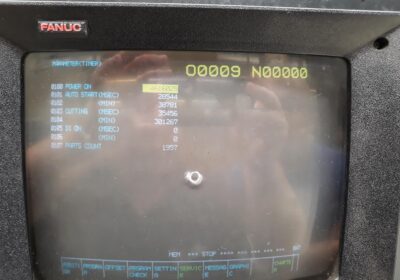

Special production line for mechanical processing of cooling elements for AC-DC-Inverter / Patented Technical specifications:-Startup of production line: 2011-Qty. work stations: 12-Qty. of conveyors: 16-Processing time for 1 unit.: Approx. 1 minute-Inverter-Size: 24 “ x 12 1/16“ x 2 13/16“-facility ground area: Approx. 20 x 36 ft.-Controller: Siemens Simatic-Conformity: CE-Proof Production steps: -Pressing cooling blades on rear surface(hydraulic)-Rotating cooling unit from rear to front side-Milling front surface with face milling cutterin 12 5/8“ daimetermilling tool-Drilling 41 vertical holes to be threadedusing 2 seperate multi-spindle-stations-Drilling 6 horizontal holes (4 threads, 2 pins)-Tapping 4 horizontal metric Threads M5 x 0,8-Tapping 41 vertical metric Threadsusing 2 seperate multi-spindle-stations-Milling both cavities on front surface(roughness Ra 0,8)-Phasing cutted edges left + right-Pressing both spring pins left + right Endproduct - Length : 609,7 mm / 24 “ - Width : 306,2 mm / 12 1/16“ - / Height: 71 mm / 2 13/16“

Prezzo: On request