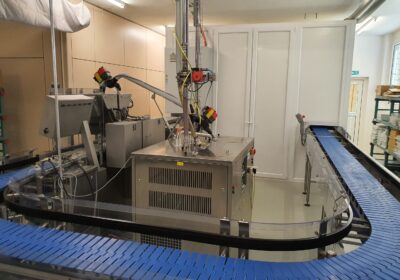

"NEW" Cerutti coating machine for Paper, films and Aluminium

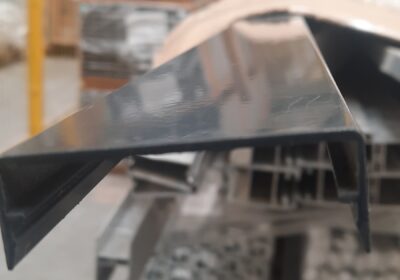

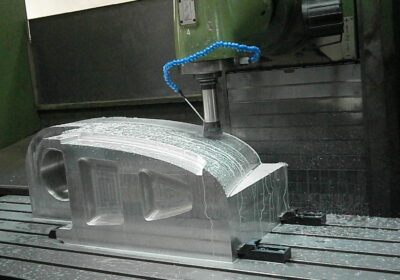

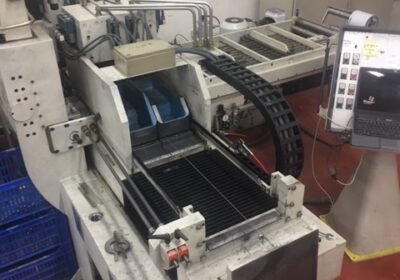

Cerutti coating machine for Paper, films and Aluminium Description: Rotogravure press for papers coating. Technology: water based. The eventual coating of aluminium and plastic films should be verified whether in compliance with the existing driving rollers. We can provide an appropriate technology, up-to-date with the latest electronic and process control systems. Below some sectors of application: -Films coating to improve both the technical and physical properties of the product (Barrier effect) as well as its printability after the film extrusion. -Paper coating pre and post vacuum metallisation Process description: The substrate is placed on the unwinder and driven to the coating units, which may change, based on the rheology of the lacquers in use. Successively the coated substrate enters the dryer, which provides for the vehicle evaporation (water). This process is repeated in line, based on the number of layers needed on the final product, with a max. of four. Next step is the rewinding of the coated substrate. The equipment is arranged for the installation of a reverse printing unit. Based on the potential positioning of the reverse unit, printing is possible in the following sequences : 1+3 – 2+2 – 3+1 The final product is then combining the physical/chemical properties of its different layers. Accessories: The equipment includes other auxiliary components like 10 rotogravure cylinders in different diameters and it is equipped with impression rollers change on sleeve system. Fiberglass sleevers are rubber-coated and are quickly inserted through compressed air. The change of cylinders takes place by the complete removal of the trolley, which includes in details: inkwell, tray, cylinder holder.