ALUROLLER

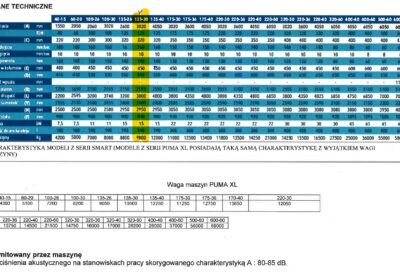

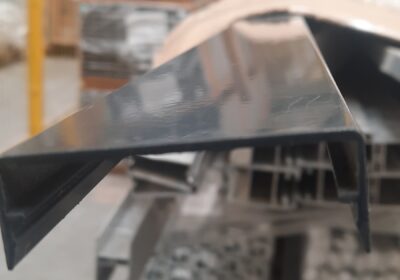

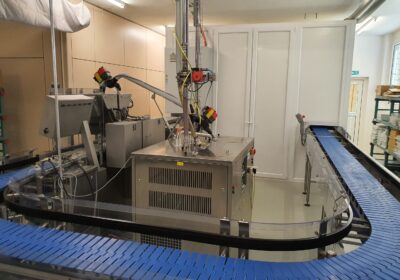

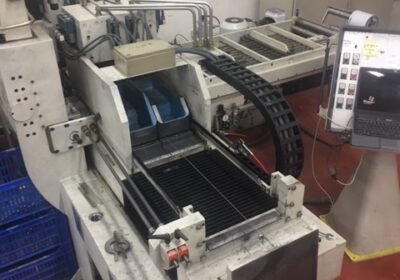

Technical specifications • Machine size : length=11 m; width=2,5 m; height=3 m • Total machine weight : ± 16000 kg • Electrical power requirements : AC 25 kW/ 3phase + PE • Mains type 3phase + Pe(TN-C, TN-C-S, TT, IT) • Voltage range: 380-440 VAC • Frequency range: 50-60 Hz • Minimum cable size: 25mm² • Recommended ELCB/RCB: 300mA type B with at least 50ms delay • Air supply : ½ “ (min. 6 bar) max. 0,25 m³/min Complete adjustment (tool changing inclusive) andlt; 5 min Change of set up (with out tool change) andlt; 1 min Change of six assembly disc (tools) 3 min Change of knurling tools 1 min Change of polyamide holders 2 min Change of profile holders (bottom) 2 min Change of profile holders (top) 3 min Max productivity (with automatic exit and packing) 130 p/h Strip dimensions: Up to 38 mm heigth Machine: • Compact design: all machines in one position • Set up driven by PLC 2. Quality: • Straight assembled profiles and Respect of geometry, no deformation or deterioration during operation • Profile stands during operation, reduced possibility of scratches when rolling over different tables 3. Crew: • Two operators or 3 for large orders • User friendly: PLC set up minimize errors 4. Productivity: • Proven cost-effectiveness for small (up to 50%!) and also big runs. • Low (or even zero set up scrap): relevant for small orders, (dual color profiles, tests, …)

Precio: On request