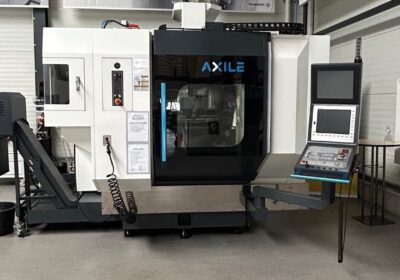

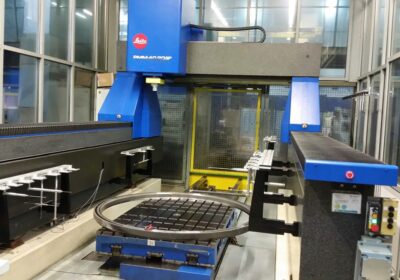

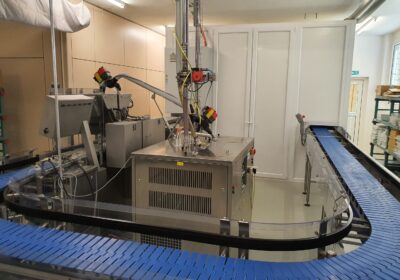

Dalcos PXN 2003

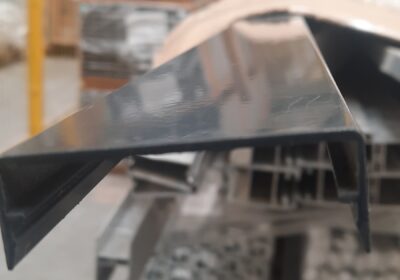

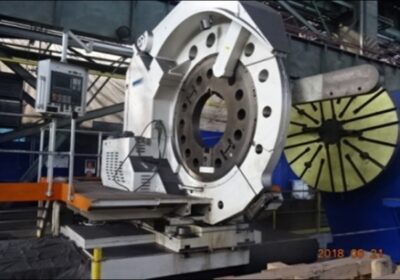

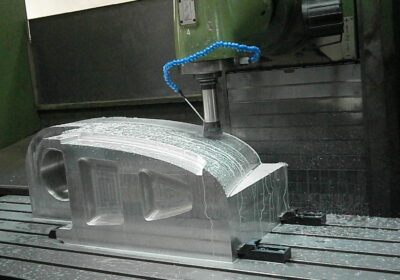

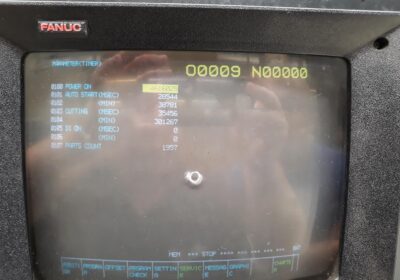

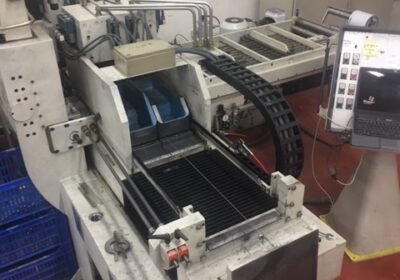

Máquina CNC para Punzonado con Sistema Dalcos Vega – Descripción y Especificaciones Esta máquina CNC ha funcionado aproximadamente 50,000 horas desde su adquisición. Se ha mantenido y lubricado de forma continua, y aunque su uso es menos frecuente actualmente, sigue operativa y en buenas condiciones. El equipo cuenta con herramientas especialmente personalizadas para nuestro proceso, permitiendo punzonar materiales de calibre fino, con un espesor mínimo de 0,2 mm, casi sin generar rebabas. La configuración de la máquina incluye cuatro arcos de herramientas, compuestos por 2 estaciones tipo C y 3 estaciones tipo B en cada uno, sumando un total de 8 estaciones C y 12 estaciones B. Los movimientos de las herramientas se realizan en la dirección Y sobre dos carretillas independientes, lo que permite la alimentación de tiras de material de hasta 400 mm de ancho. El sistema de alimentación CNC utiliza el alimentador patentado Dalcos Vega, que garantiza una alimentación precisa y eficiente. La fuerza de punzonado es proporcionada por una unidad hidráulica de 250 psi, que entrega hasta 8 toneladas de fuerza en cada estación. Además, el material es cortado al finalizar el proceso de punzonado mediante un cuchillo de corte con capacidad de 10 toneladas. El control del equipo se realiza mediante una consola PC que gestiona el armario eléctrico. La tira de material se desenrolla de un desenrollador con capacidad de 1,25 toneladas, que dispone de control manual y automático para el manejo de la tensión (loop control). La máquina incluye soportes personalizados para las herramientas en todas las estaciones (tanto B como C), con portamatrices autocentrantes en cada soporte, facilitando un ajuste preciso y eficiente. Si se desea, los arcos de herramientas pueden ser reemplazados para usar herramientas estándar Amada thick turret u otros tipos, a través de una gestión con Dalcos Italia. Palabras clave SEO destacadas: máquina CNC para punzonado prensa hidráulica para punzonado alimentador Dalcos Vega punzonado de chapas finas 0,2 mm procesamiento de chapa metálica herramientas compatibles Amada prensa CNC usada en España estaciones de herramientas tipo B y C alimentación automática de chapas maquinaria industrial para metalurgia