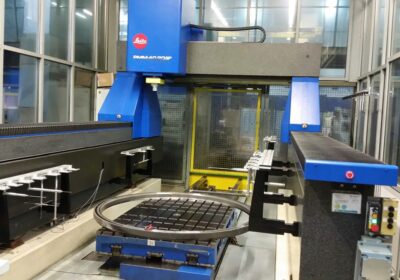

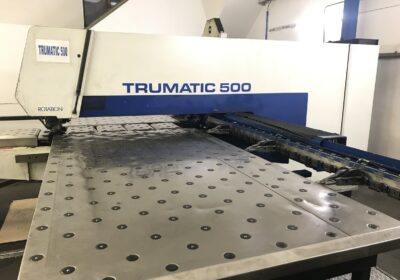

Trumpf Trumatic 600L

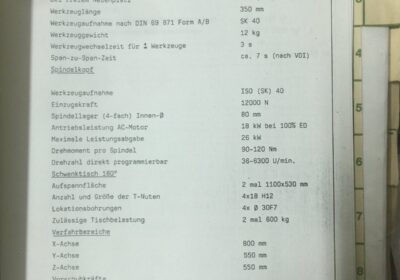

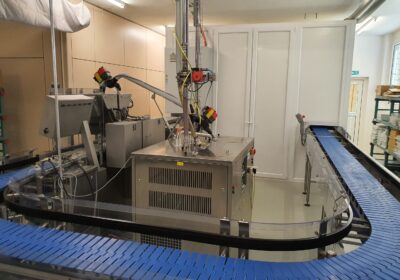

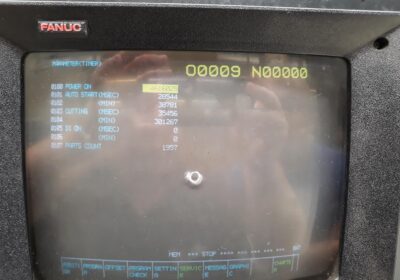

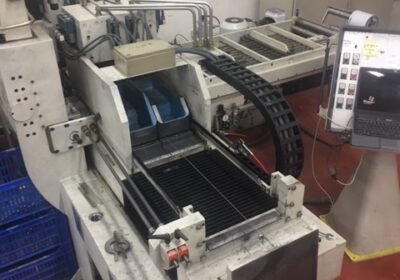

Trumpf Trumatic 600L The TRUMPF Trumatic 600L is a high-performance laser and punching combination machine, designed to perform both laser cutting and punching/forming in a single setup. This model combines the flexibility of laser processing with the speed and versatility of turret punching, allowing efficient fabrication of complex sheet metal parts. It is especially well-suited for medium to large-scale production in industries requiring both high precision and varied forming capabilities. Technical Specifications (Note: specs can vary by year/model revision) Working Area (X × Y): Approx. 2500 mm × 1250 mm (standard sheet size) Some variants allow repositioning for longer sheets (up to 3000 mm) Laser Type: CO₂ laser Typical power: 2.4 kW or 3.2 kW TRUMPF TLF laser Punching Force: 180 kN (approx. 18 tons) Max Sheet Thickness: Laser Cutting: Mild Steel: up to 8 mm Stainless Steel: up to 4 mm Aluminum: up to 3–4 mm Punching/Forming: Typically up to 6.4 mm (depending on tool and material) Axis Speeds: Rapid traverse: Up to 90 m/min Simultaneous positioning speed (X+Y): ~127 m/min Accuracy: Positioning: ±0.1 mm Repeatability: ±0.03 mm Tooling System: Rotating turret head with multi-tool stations Supports indexable tools for complex forming (lances, embossing, countersinks, etc.) Control System: Typically equipped with Siemens Sinumerik or TRUMPF CNC control Graphical user interface, part nesting, and program simulation included Automation Options: Sheet loading/unloading automation Part removal conveyors Tool changer automation Integration into TRUMPF's TruStore or LiftMaster systems Typical Applications TruMatic 6000 Price TruMatic 5000R TRUMPF punch laser combo Sheet metal fabrication with both cutting and forming HVAC components (e.g. ducting with lances or flanges) Electrical enclosures Appliance panels Machine covers and frames Control cabinets Custom perforated panels The Trumatic 600L allows: Cutting complex outer contours and internal cutouts by laser Punching holes, embossing, countersinking, and tapping in a single pass Lower handling time due to combined process